Ultra-High-Performance Concrete is Ready to Revolutionize Precast, Prestressed Concrete

Fiber-reinforced, cement-based UHPC has the potential to change building and bridge design

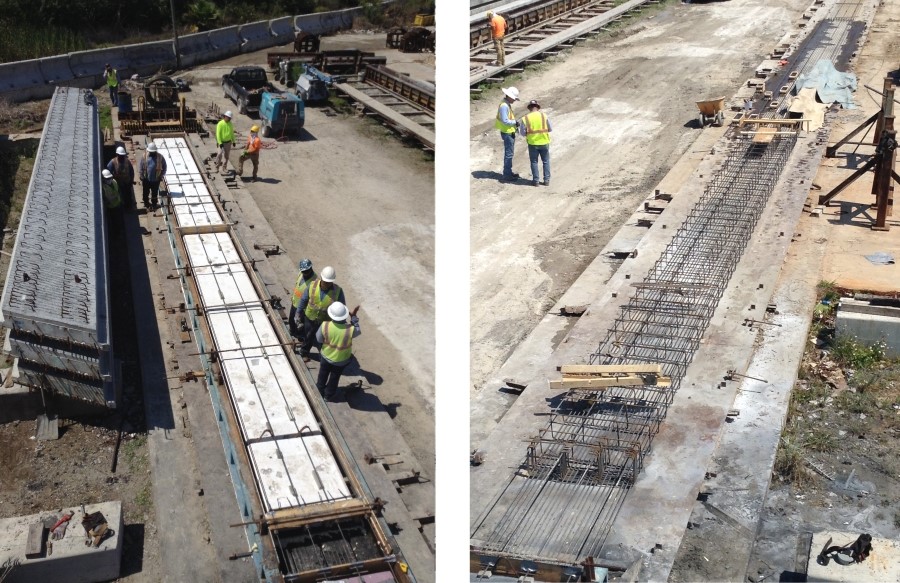

Right: conventional concrete box slab showing reinforcement (prior to formwork installation); Left: optimized UHPC box slab (with formwork and foam void-forming blockout in place). Images Courtesy of Precast/Prestressed Concrete Institute

The following article is from ENR (Engineering News-Record)

E.Construct.USA, LLC’s Managing Partner, Dr. Maher Tadros, co-authored this article.

April 23, 2020

John S. Lawler, Elizabeth I. Wagner, and Maher K. Tadros

KEYWORDS Admixtures / bridge / building / Concrete / Concrete application / design / High-Performance / mixtures / PCI / Precast / Precast/Prestressed Concrete / Prestressed / research / Techology / UHPC / Ultra High-Performance Concrete / University of Nebraska / WJE

Lawler

Ultra-high-performance concrete (UHPC) is rapidly emerging as a premier material for precast concrete construction. First introduced as “reactive powder concrete” in the early 1990s, this material has seen growing usage in the U.S. and abroad over the past decade.

UHPC has been used to construct roadway bridges in France, Japan, and Malaysia; pedestrian bridges in Canada and Venezuela; roof panels and architectural facades in Canada and France; and more.

Wagner

In the U.S., UHPC has been used to construct bridge beams in Virginia and Iowa, bridge deck overlays in New York and Delaware, and field-cast joints between precast bridge members in more than 20 other states. Ongoing research and development efforts by federal and state transportation agencies, national industry organizations, private owners, and concrete producers are seeking to further advance this technology so that it can be more broadly adopted in both the transportation and building construction sectors.

Tadros

One key industry well-suited to capitalize on the unique performance characteristics of this material is the precast prestressed concrete industry.

What is UHPC?

UHPC is a fiber-reinforced, cement-based material. It contains many of the same materials as conventional concrete — cement, supplementary cementitious materials (SCMs), fine sand, and chemical admixtures — but the materials are proportioned to create a dense packing of materials from the silica fume to the sand, i.e. from the finest to the coarsest materials.

Total cementitious materials contents for UHPC mixtures can and often do exceed 1,500 lbs per cu yd of material — more than double the cementitious materials contents of most conventional concrete mixtures. However, the water-to-binder ratio (w/b) is often 0.20 or less, facilitated by the use of specialty high-range water reducers. The dense particle packing, combined with the ultra-low w/b, creates in the concrete a highly refined microstructure that provides exceptional strength and durability. As a result, UHPC elements can have a life expectancy of 200 years or more, even in demanding environments such as marine and deicing exposures.

While there is no uniformly agreed upon definition of UHPC, typical UHPC compressive strengths are in excess of 17,000 psi, with many commercially available UHPC materials able to achieve strengths of 30,000 psi or more. Compared to conventional and high-performance concretes, UHPC can provide a 3- to 5-fold increase in compressive strength. However, compressive strength is not the most significant property of this material. A key differentiator between structural UHPC and other classes of concrete, especially for structural precast applications, is the material’s high tensile performance, which derives from a combination of the refined microstructure and the high-strength steel microfibers that are incorporated into the mixture at dosages between about 1 and 3%, by volume (about 130 to 390 lbs/cu yd).

Structural UHPC mixtures can be designed to achieve direct tensile strengths of more than 1,000 psi, and flexural strengths of more than 2,500 psi. Moreover, a well-designed UHPC mixture can exhibit significant post-cracking ductility and strain hardening, significantly increasing residual flexural strength as the element deflects after cracking.

The high tensile strength and post-cracking ductility of UHPC provides significant benefit for structural design. First, the post-cracking ductility and strain hardening behavior can allow for the virtual elimination of the minimum reinforcing bars required in conventional concrete to achieve code-mandated ductility when failure is imminent.

Second, the high ductility of the UHPC results in a tremendous material toughness, which increases the ability to absorb energy even without help from the reinforcing bars.

Third, the high tensile strength increases the shear resistance of the material, with the possibility of total elimination of shear stirrups in beam design. By eliminating the stirrups, element design and production can be simplified, and member web (stem) widths can be reduced. In fact, beams, columns and other UHPC structural members can be designed with cross-sections having much less volume, and thus weight, of material while providing the same capacity as conventionally reinforced concrete members.

Advancing Technology for Precast, Prestressed Concrete

UHPC shows considerable promise for advancing the capabilities of the precast, prestressed concrete industry. The performance characteristics of this material can allow for the design of structural systems that maintain acceptable strength and serviceability while having reduced member weights, extended span lengths, and less reinforcing. Moreover, with the high durability afforded by this material, these structural systems can be deployed in demanding environments, such as marine applications and cold-weather exposures, as low cost-benefit ratio alternatives to designs utilizing stainless steel and non-metallic reinforcing bars.

For UHPC to see widespread implementation in the precast prestressed concrete industry, two conditions need to be met: (1) UHPC must be able to be produced reliably at precast facilities, with raw materials costs totaling less than $1,000 per cu yd (compared to current costs of $2,000 to $3,000 per cu yd for pre-bagged materials); and (2) procedures must be developed to enable the design of structural systems that capitalize on the unique performance characteristics of the UHPC. Such procedures can provide tremendous value by enabling approximately 50% reduction in cross section compared to conventional concrete products.

The Precast/Prestressed Concrete Institute (PCI) has recognized this need and devoted resources to support a research project for the benefit of the industry. The overall project and design guideline development are being led by e.construct of Omaha, Neb., while the materials aspects of the project have been led by two of the authors’ firm, Wiss, Janney, Elstner Associates of Northbrook, Ill.

The primary goals of this project are to develop methods for implementing cost-effective UHPC mixes based on locally available materials at precaster facilities throughout North America and to develop design guidelines and novel designs for optimized structural members for buildings and bridges.

To date, the project team has developed guidelines and recommendations for designing and implementing UHPC mixtures at precast prestressed concrete production facilities and has validated these procedures through production at five such facilities across the U.S. (see Figure 1 for example UHPC placement at one of the participating precasters).

In addition, prototypes of long-span bridge and building elements have been designed, produced, and tested by the project team, with the ultimate member strengths exceeding the design service loads. It is anticipated that despite the initial high cost of the UHPC materials, the optimized designs and reduced member cross-sections will make these UHPC products competitive with conventional concrete and steel alternatives on an initial cost basis. The progress to date has been summarized in a Phase I report published in February.

Figure 1. Placement of UHPC, demonstrating self-consolidating consistency.

Example Applications of Optimized UHPC Members

Using UHPC, it is now possible to design office building floors with column-free bays that are 60-ft by 60-ft, allowing for great flexibility in interior design of leased space. It is also possible to develop bridge beams as long as 250 ft, within acceptable shipping and erection limits, and without the need for field shoring or splicing. The following two examples illustrate the strong potential of UHPC applications.

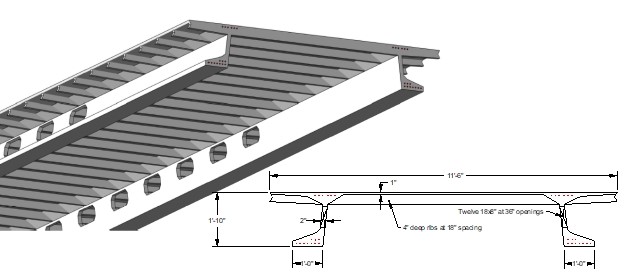

Figure 2 shows a design concept for use in buildings. The “π” shaped cross section is a precast, prestressed floor panel that allows for a 60-ft span using a depth of 22 inches. No steel, other than the prestressing strands, is needed for this design. The top flange is only 1-inch thick and the stems are only 2-inches wide. The overall weight corresponds to a solid slab less than 3 inches thick. Installed, the soffit would be closed in with light gage joists stretching between the stems and covered with gypsum board, and the stems have openings to allow for integration of utilities. With this long-span product, residential multistory buildings can have column-free parking in the lower floors, which enhances the efficiency of the space utilization and the safety of the residents. The relatively shallow structural depth — incorporating the mechanical, electrical and plumbing systems — provides for efficient use of space and cost-effective story height.

Figure 2. Concept of a UHPC Slab System for Residential applications

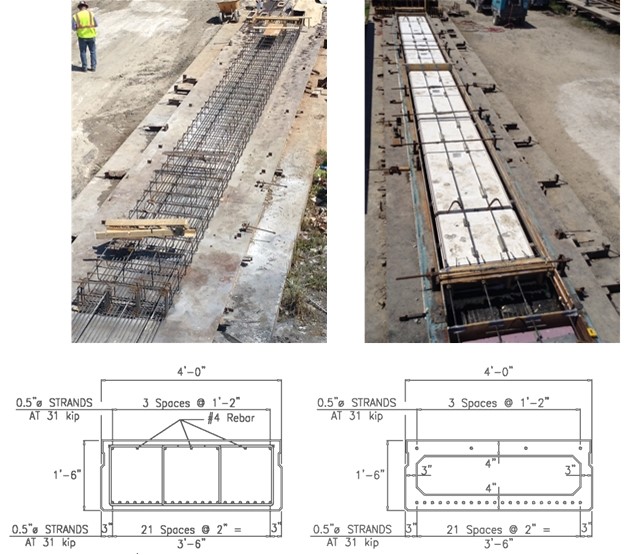

Figure 3 shows a conventional concrete slab beam used for 40- to 60-ft spans in accelerated bridge construction (ABC) applications. The figure also shows an optimized UHPC voided box slab using the same depth, width and load capacity. The UHPC product has about 52% of the concrete and less than 4% of the rebar, compared with the similar conventional concrete beam. Full-scale testing by the Florida DOT Structural Laboratory demonstrated that this beam design has much higher flexural, shear, punching shear and transverse capacity than required for the bridge. Further refinements in the element design could justify a reduction in the number of strands used, which were kept the same as for the conventional concrete product for this demonstration.

Figure 3. Box slab for bridge applications. Left: conventional concrete box slab showing reinforcement (prior to formwork installation); Right: optimized UHPC box slab (with formwork and foam void-forming blockout in place).

Conclusion

UHPC has the potential to revolutionize the precast, prestressed concrete industry, especially in large-scale applications, where long spans or enhanced durability are beneficial. With novel designs and emerging design procedures, UHPC has the ability to be cost-competitive with conventional concrete and steel alternatives on a first-cost basis, and can provide additional value on a long-term life-cycle cost basis. By taking advantage of the key properties in UHPC, long-span precast, prestressed bridge and building members will revolutionize the industry, through their more efficient use of materials, improved space utilization, and enhanced long-term performance.